Scheduled waste management is a critical aspect of environmental protection and public health in Malaysia. Under the Environmental Quality (Scheduled Wastes) Regulations 2005, scheduled waste is defined as any waste falling within the categories of waste listed in the First Schedule of the regulations that poses potential harm to human health or the environment due to its toxic, flammable, corrosive, or infectious nature. Proper management of scheduled waste is essential to prevent pollution, conserve natural resources, and ensure sustainable development.

In Malaysia, the Department of Environment (DOE) plays a pivotal role in regulating and monitoring scheduled waste management. The Environmental Quality (Scheduled Wastes) Regulations 2005 provide a comprehensive framework for the handling, storage, transportation, and disposal of scheduled waste. These regulations ensure that industries, businesses, and waste management service providers adhere to strict guidelines to minimize environmental impact.

The importance of effective scheduled waste management cannot be overstated. Improper disposal of scheduled waste can lead to severe consequences, including soil and water contamination, air pollution, and long-term health risks for communities. By implementing robust waste management practices, Malaysia aims to achieve its environmental sustainability goals while fostering economic growth.

In this article, we will explore the regulatory framework, classification, responsibilities, and best practices for scheduled waste management in Malaysia. Whether you are a business owner, environmental professional, or concerned citizen, this guide will provide valuable insights into managing scheduled waste responsibly and sustainably.

Understanding Scheduled Waste

What is Scheduled Waste?

Scheduled waste refers to any waste material that is classified as hazardous listed under the First Schedule of Environmental Quality (Scheduled Wastes) Regulations 2005 in Malaysia. These wastes pose significant risks to human health and the environment due to their toxic, corrosive, flammable, or reactive properties.

Some common examples of scheduled waste in Malaysia include:

- Used oil and lubricants: Often classified under SW 305, these wastes require specialized treatment to recover valuable resources or render them safe for disposal.

- Electronic waste (e-waste): Items like discarded computers, mobile phones, and home appliances fall under SW 110 and must be recycled or treated to recover metals and other materials.

- Chemical sludge: Generated by industries such as manufacturing and petrochemicals, chemical sludge (e.g., SW 204) is highly toxic and requires careful handling and disposal.

Types of Scheduled Waste Generated by Manufacturers

Manufacturers in Malaysia often generate the following types of scheduled waste:

- Corrosive Wastes: Acids and alkalis that can damage living tissue and materials (e.g., spent acid from metal cleaning processes).

- Flammable Wastes: Liquids or solids that can easily ignite (e.g., solvents, paints, and adhesives).

- Toxic Wastes: Substances that can cause harm if inhaled, ingested, or absorbed through the skin (e.g., heavy metals like lead and mercury).

- Reactive Wastes: Materials that can explode or release toxic gases when exposed to water, air, or other chemicals (e.g., peroxides and cyanides).

- Infectious Wastes: Waste contaminated with pathogens, often generated in pharmaceutical or healthcare-related manufacturing.

With 77 types of scheduled wastes in 5 main categories identified (as listed in the table below), each assigned a unique scheduled waste code, effective management is essential to ensure compliance with Malaysian regulations. Proper scheduled waste storage, treatment, and scheduled waste disposal play a vital role in mitigating environmental pollution and supporting sustainable development initiatives.

Key Legal and Regulatory Frameworks

Environmental Quality Act 1974 (Act 127)

The regulatory framework for scheduled waste management in Malaysia is structured to uphold stringent environmental standards. Central to this framework is the Environmental Quality Act 1974 (Act 127), the cornerstone legislation for environmental protection in the country. This Act establishes a comprehensive system of regulations, enforcement mechanisms, and funding provisions, forming the foundation of Malaysia’s approach to pollution control and environmental sustainability. It grants the DOE the authority to enforce these regulations and oversee compliance across various industries.

Environmental Quality (Scheduled Wastes) Regulations 2005

A key component of the regulatory framework is the Environmental Quality (Scheduled Wastes) Regulations 2005, enacted under the authority of the Environmental Quality Act 1974. These regulations provide a detailed and systematic approach to the management of scheduled wastes, outlining the responsibilities of various stakeholders. They specify requirements for the identification, handling, storage, transportation, treatment, and disposal of scheduled waste. Additionally, the regulations mandate that all scheduled waste transporters and facilities secure the necessary licenses from the DOE. Non-compliance with these regulations can lead to significant penalties, including hefty fines, legal action, or the suspension of operations.

The DOE plays a central role in enforcing these regulations. It conducts regular inspections, audits, and monitoring to ensure that businesses and waste management service providers comply with the law. Additionally, the DOE maintains the Electronic Scheduled Waste Information System (eSWIS), an online platform where waste generators must submit detailed reports on the types and quantities of scheduled waste they produce. This system enhances transparency and accountability in scheduled waste management.

Licensing is a critical aspect of the regulatory framework, where the transporters and disposal/treatment facilities require a Scheduled Waste Transporter License and Scheduled Waste Facility License, respectively. These licenses ensure that only qualified and authorized entities are involved in the management of scheduled waste, reducing the risk of illegal dumping or improper disposal.

Overall, the Scheduled Waste Regulations 2005 play a vital role in operationalizing the Environmental Quality Act 1974’s broad environmental protection goals. By establishing clear procedures and responsibilities for the handling, storage, transportation, treatment, and disposal of hazardous wastes, these regulations contribute significantly to safeguarding environmental quality and public health in Malaysia.

Classification of Scheduled Waste

Proper scheduled waste management begins with the accurate classification of waste materials. In Malaysia, scheduled waste is categorized based on its characteristics and potential hazards, as outlined in the Environmental Quality (Scheduled Wastes) Regulations 2005. This classification system ensures that each type of waste is handled, treated, and disposed of in a manner that minimizes risks to the environment and public health.

List of Scheduled Waste Codes

Under the First Schedule of Environmental Quality (Scheduled Wastes) Regulations 2005, scheduled waste is assigned specific waste codes as shown in the table below, which are used to identify and categorize different types of waste. These codes are essential for tracking and reporting purposes.

| SW Code | Waste Type |

|---|---|

| SW1 Series | Metal and Metal-Bearing Waste |

| SW101 | Waste containing arsenic or its compounds. |

| SW102 | Waste of lead acid batteries in whole or crushed form. |

| SW103 | Waste of batteries containing cadmium and nickel or mercury or lithium. |

| SW104 | Dust, slag, dross or ash containing arsenic, mercury, lead, cadmium, chromium, nickel, copper, vanadium, beryllium, antimony, tellurium, thallium or selenium excluding slag from iron and steel factory. |

| SW105 | Galvanic sludges. |

| SW106 | Residues from recovery of acid pickling liquor. |

| SW107 | Slags from copper processing for further processing or refining containing arsenic, lead or cadmium. |

| SW108 | Leaching residues from zinc processing in dust and sludges form. |

| SW109 | Waste containing mercury or its compound. |

| SW110 | Waste from electrical and electronic assemblies containing components such as accumulators, mercury-switches, glass from cathode-ray tubes and other activated glass or polychlorinated biphenyl-capacitors, or contaminated with cadmium, mercury, lead, nickel, chromium, copper, lithium, silver, mangane. |

| SW2 Series | Wastes containing principally inorganic constituents |

| SW201 | Asbestos wastes in sludges, dust or fibre forms. |

| SW202 | Waste catalysts. |

| SW203 | Immobilized scheduled wastes including chemically fixed, encapsulated, solidified or stabilized sludges. |

| SW204 | Sludges containing one or several metals including chromium, copper, nickel, zinc, lead, cadmium, aluminium, tin, vanadium and beryllium. |

| SW205 | Waste gypsum arising from chemical industry or power plant. |

| SW206 | Spent inorganic acids. |

| SW207 | Sludges containing fluoride. |

| SW3 Series | Waste containing principally organic constituents |

| SW301 | Spent organic acids with pH less or equal to 2 which are corrosive or hazardous. |

| SW302 | Flux waste containing mixture of organic acids, solvents or compounds of ammonium chloride. |

| SW303 | Adhesive or glue waste containing organic solvents excluding solid polymeric materials. |

| SW304 | Press cake from pretreatment of glycerol soap lye. |

| SW305 | Spent lubricating oil. |

| SW306 | Spent hydraulic oil. |

| SW307 | Spent mineral oil-water emulsion. |

| SW308 | Oil tanker sludges. |

| SW309 | Oil-water mixture such as ballast water. |

| SW310 | Sludge from mineral oil storage tank. |

| SW311 | Waste oil or oily sludge. |

| SW312 | Oily residue from automotive workshop, service station, oil or grease interceptor. |

| SW313 | Oil contaminated earth from re-refining of used lubricating oil. |

| SW314 | Oil or sludge from oil refinery plant maintenance operation. |

| SW315 | Tar or tarry residues from oil refinery or petrochemical plant. |

| SW316 | Acid sludge. |

| SW317 | Spent organometallic compounds including tetraethyl lead, tetramethyl lead and organotin compounds. |

| SW318 | Waste, substances and articles containing or contaminated with polychlorinated biphenyls (PCB) or polychlorinated triphenyls (PCT). |

| SW319 | Waste of phenols or phenol compounds including chlorophenol in the form of liquids or sludges. |

| SW320 | Waste containing formaldehyde. |

| SW321 | Rubber or latex wastes or sludge containing organic solvents or heavy metals. |

| SW322 | Waste of non-halogenated organic solvents. |

| SW323 | Waste of halogenated organic solvents. |

| SW324 | Waste of halogenated or unhalogenated non-aqueous distillation residues arising from organic solvents recovery process. |

| SW325 | Uncured resin waste containing organic solvents or heavy metals including epoxy resin and phenolic resin. |

| SW326 | Waste of organic phosphorus compound. |

| SW327 | Waste of thermal fluids (heat transfer) such as ethylene glycol. |

| SW4 Series | Waste which may contain either inorganic or organic constituents |

| SW401 | Spent alkalis containing heavy metals. |

| SW402 | Spent alkalis with pH more or equal to 11.5 which are corrosive or hazardous. |

| SW403 | Discarded drugs containing psychotropic substances or containing substances that are toxic, harmful, carcinogenic, mutagenic or teratogenic. |

| SW404 | Pathogenic wastes, clinical wastes or quarantined materials. |

| SW405 | Waste arising from the preparation and production of pharmaceutical product. |

| SW406 | Clinker, slag and ashes from scheduled wastes incinerator. |

| SW407 | Waste containing dioxins or furans. |

| SW408 | Contaminated soil, debris or matter resulting from cleaning-up of a spill of chemical, mineral oil or scheduled wastes. |

| SW409 | Disposed containers, bags or equipment contaminated with chemicals, pesticides, mineral oil or scheduled wastes. |

| SW410 | Rags, plastics, papers or filters contaminated with scheduled wastes. |

| SW411 | Spent activated carbon excluding carbon from the treatment of potable water and processes of the food industry and vitamin production. |

| SW412 | Sludges containing cyanide. |

| SW413 | Spent salt containing cyanide. |

| SW414 | Spent aqueous alkaline solution containing cyanide. |

| SW415 | Spent quenching oils containing cyanides. |

| SW416 | Sludges of inks, paints, pigments, lacquer, dye or varnish. |

| SW417 | Waste of inks, paints, pigments, lacquer, dye or varnish. |

| SW418 | Discarded or off-specification inks, paints, pigments, lacquer, dye or varnish products containing organic solvent. |

| SW419 | Spent di-isocyanates and residues of isocyanate compounds excluding solid polymeric material from foam manufacturing process. |

| SW420 | Leachate from scheduled waste landfill. |

| SW421 | A mixture of scheduled wastes. |

| SW422 | A mixture of scheduled and non-scheduled wastes. |

| SW423 | Spent processing solution, discarded photographic chemicals or discarded photographic wastes. |

| SW424 | Spent oxidizing agent. |

| SW425 | Wastes from the production, formulation, trade or use of pesticides, herbicides or biocides. |

| SW426 | Off-specification products from the production, formulation, trade or use of pesticides, herbicides or biocides. |

| SW427 | Mineral sludges including calcium hydroxide sludges, phosphating sludges, calcium sulphite sludges and carbonates sludges. |

| SW428 | Wastes from wood preserving operation using inorganic salts containing copper, chromium or arsenic of fluoride compounds or using compound containing chlorinated phenol or creosote. |

| SW429 | Chemicals that are discarded or off-specification. |

| SW430 | Obsolete laboratory chemicals. |

| SW431 | Waste from manufacturing or processing or use of explosives. |

| SW432 | Waste containing, consisting of or contaminated with, peroxides. |

| SW5 Series | Other wastes |

| SW501 | Any residues from treatment or recovery of scheduled wastes. |

Each waste code corresponds to a particular type of scheduled waste, making it easier for waste generators, transporters, and facility operators to manage waste streams effectively. The classification system also helps the DOE monitor and regulate scheduled waste activities across the country.

Accurate classification is crucial because it determines the appropriate management practices for each type of waste. Misclassification can lead to improper handling, which may result in environmental contamination or legal penalties. Waste generators must ensure that their scheduled waste is correctly identified and labeled before it is transported or treated.

Responsibilities of Waste Generators

Effective scheduled waste management in Malaysia places significant responsibilities on waste generators to ensure compliance with the Environmental Quality (Scheduled Wastes) Regulations 2005. These responsibilities are designed to minimize environmental risks and ensure the safe handling, storage, transportation, and disposal of scheduled waste. Below are the key responsibilities of waste generators as outlined in the regulations:

Notification of Scheduled Waste Generation

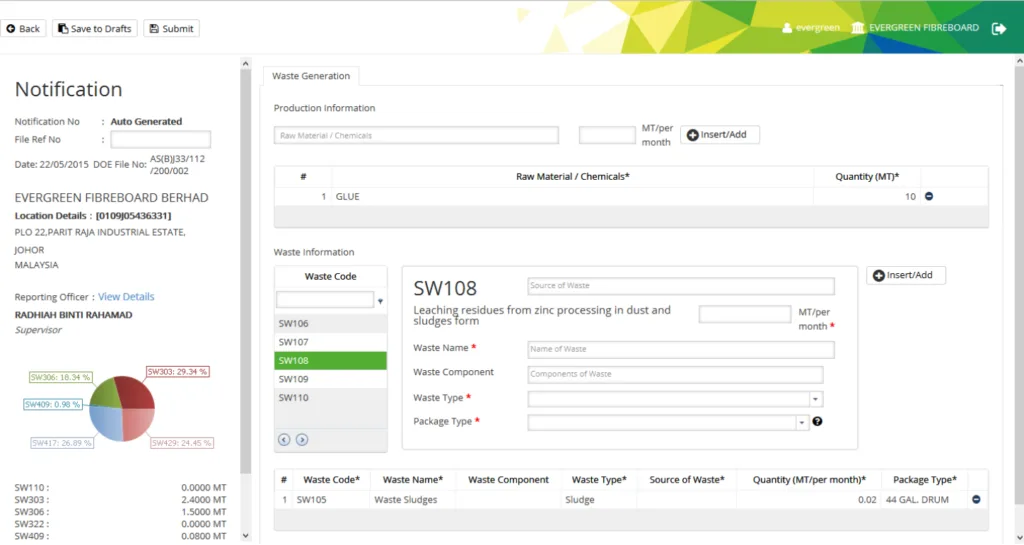

Under Regulation 3, waste generators are required to notify the Director General of Environmental Quality within 30 days of generating new categories or quantities of scheduled waste. This ensures that the DOE maintains an accurate record of scheduled waste activities across the country. This notification must include the following information as specified in the Second Schedule, which the submission of notification can be done via eSWIS portal.

- Identification: This section includes the name and address of the premise where the waste is generated, along with contact information including telephone, fax, and telex numbers. It also requires the name and designation of the premise owner.

- Production Data: This section requires waste generators to list the raw materials and chemicals used each month, specifying the quantity in metric tons for each item.

- Waste Data: This section lists the scheduled wastes generated each month. For each waste category code, the waste generator must provide the waste source, name of the waste, waste components, and the estimated quantity in tons per month. The waste source should refer to the unit operation in the process or plant, and the waste components should list the elements, compounds, or materials present.

- Certification: The notification form also includes a certification statement that the information provided is true and correct to the best of the reporting officer’s knowledge. The reporting officer refers to the person handling the scheduled wastes.

Proper Storage of Scheduled Waste

Regulation 9 mandates that waste generators store scheduled waste in compatible, durable containers that prevent spillage or leakage. Incompatible scheduled wastes (as listed in the Fourth Schedule) must be stored in separate containers and placed in secondary containment areas to avoid hazardous reactions. Waste generators are also required to ensure that storage areas are designed and maintained to prevent environmental contamination.

Storage Limits and Permits

- 180-Day Rule: Scheduled waste can only be stored on-site for a maximum of 180 days. After this period, it must be treated, disposed of, or sent to a prescribed facility.

- 20 Metric Tonnes Limit: The total quantity of scheduled waste stored on-site must not exceed 20 metric tonnes unless prior approval is obtained from the DOE.

- Off-Site Storage: If manufacturers need to store more than 20 metric tonnes or require longer storage periods, they must apply for written approval from the Director General.

For detailed guidelines on the proper storage management of scheduled waste, please refer to the section titled Designing and Managing Storage Areas below.

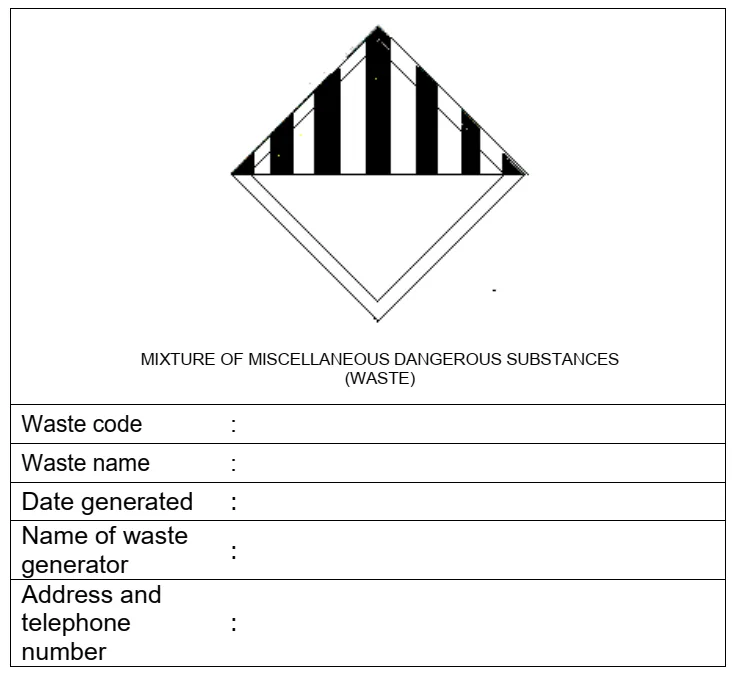

Accurate Labelling of Scheduled Waste

Regulation 10 requires waste generators to clearly label all containers of scheduled waste to ensure proper identification and promote safe handling of these wastes. Here are the key provisions of Regulation 10:

- Labelling Requirements: Containers storing scheduled wastes must be clearly labeled with the following information:

- The date the waste was first generated

- The name, address, and telephone number of the waste generator

- Identification and Warning Labels: In addition to the basic information above, the containers must also display labels according to the waste types specified in the Third Schedule of the regulations. Each label must include the corresponding scheduled waste code as outlined in the First Schedule. These labels use standardized symbols and colors to quickly communicate the hazards associated with the waste, like flammability, toxicity, and corrosivity.

- Prohibition of Alterations: No one is permitted to alter the markings and labels on containers of scheduled wastes.

For detailed guidelines on labelling of scheduled waste, please refer to the section below titled Proper Labelling of Containers.

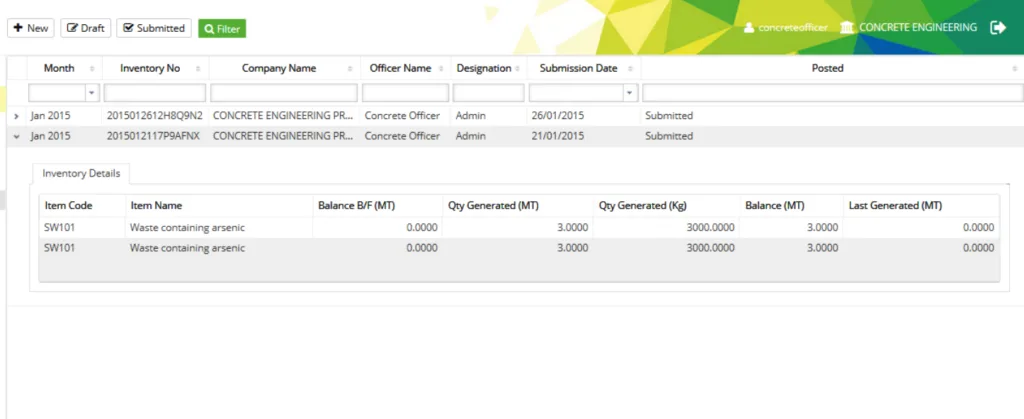

Maintenance of Inventory Records

Waste generators must keep an accurate and up-to-date inventory of all scheduled waste generated, treated, and disposed of, as per Regulation 11. The Fifth Schedule of the regulations provides a sample inventory form that waste generators can use. This form includes fields for recording:

- Information of Scheduled Waste:

- The date the waste was first generated

- The waste category code

- The name of the waste

- The quantity of waste generated (in metric tons)

- The waste handling method (e.g., stored, processed, recovered, incinerated)

- The quantity of waste managed by each method (in metric tons)

- The location where the waste was handled

- Declaration: The inventory form also includes a declaration statement where the reporting officer (the person handling the scheduled wastes) confirms that all the information provided is accurate and true to the best of their knowledge.

Nevertheless, with the eSWIS system, waste generators can now effortlessly manage their scheduled waste inventory, streamlining compliance and enhancing efficiency.

Engagement of Licensed Contractors

Waste generators are responsible for ensuring that scheduled waste is transported and treated only by licensed transporters and facilities. You can visit the eSWIS Portal to verify whether a transporter or facility is licensed.

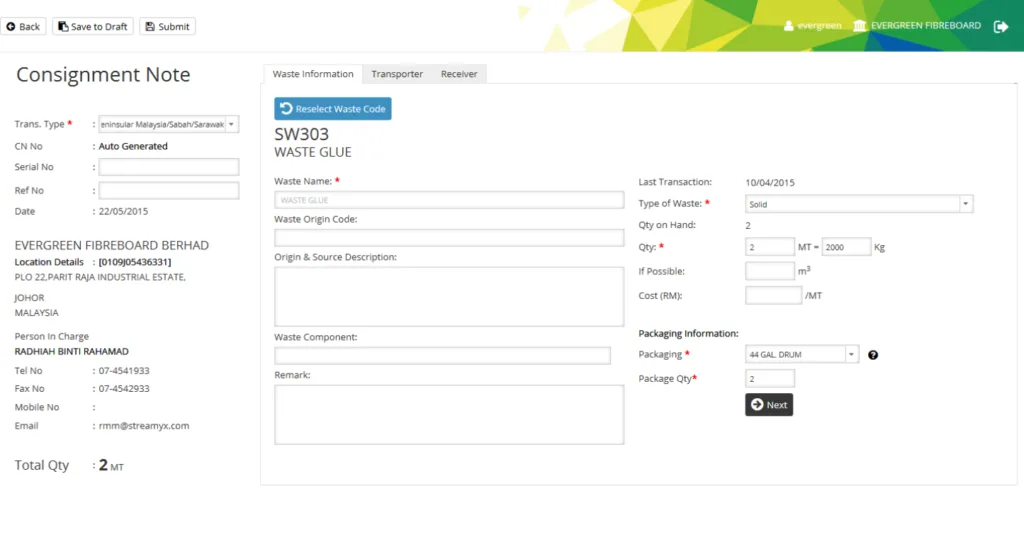

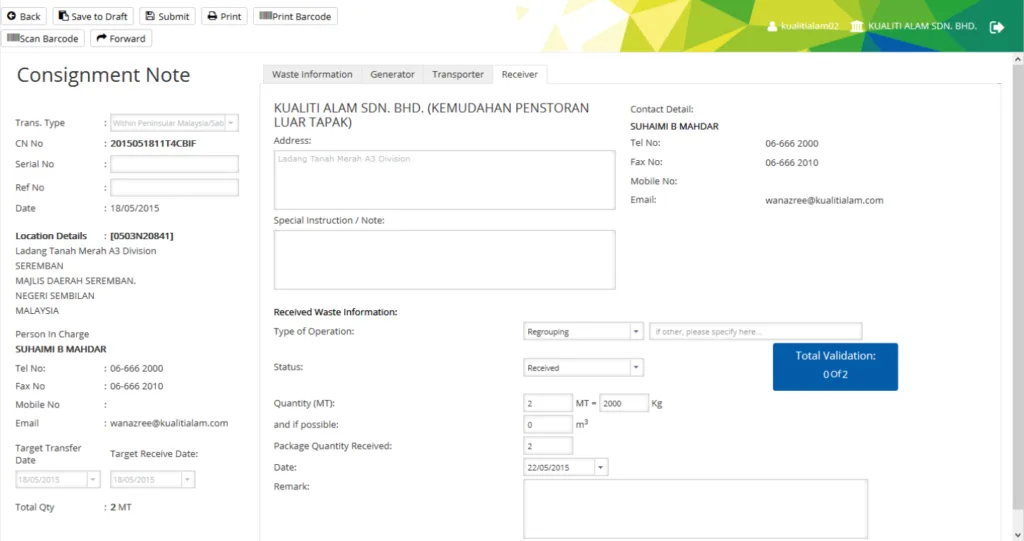

Waste generators are required to create a Consignment Note using eSWIS system that includes details such as the waste category, quantity, destination as well as the details of transporter and receiver. This consignment note essentially establishes a chain of custody documentation system for scheduled wastes in Malaysia, promoting transparency and accountability in the waste management process.

Spill or Accidental Discharge Response

In the event of a spill or accidental discharge of scheduled waste, waste generators must provide technical expertise and support to the contractor for containment and cleanup, as per Regulation 14. This collaborative approach ensures that the cleanup is conducted effectively and efficiently, leveraging the specific knowledge the generator may have about the waste’s characteristics.

Employee Training

Regulation 15 requires waste generators to ensure that their employees who handle scheduled wastes are competent in the following areas:

- Identification of different types of scheduled wastes.

- Safe handling procedures to minimize the risk of exposure or accidents.

- Proper labelling of waste containers to ensure clear identification and communication of hazards.

- Safe transportation practices to prevent spills or leaks during transit.

- Secure storage of scheduled wastes to prevent environmental contamination.

- Appropriate response procedures in case of spills or accidental discharges.

By mandating employee training, Regulation 15 aims to create a workforce that is knowledgeable and skilled in the safe management of scheduled wastes. This helps to minimize accidents, prevent environmental pollution, and protect public health.

Compliance with Audits and Inspections

Waste generators must be prepared for audits and inspections by the DOE to verify compliance with scheduled waste regulations. Non-compliance can result in penalties, fines, or legal action.

Special Management of Scheduled Waste

Under Regulation 7 of the Environmental Quality (Scheduled Wastes) Regulations 2005, waste generators have the option to apply for special management of their scheduled waste. This provision allows businesses to request that their specific waste streams be excluded from standard treatment, disposal, or recovery processes at off-site facilities. Instead, the waste can be managed exclusively at prescribed premises or on-site treatment or recovery facilities, provided the Director General approves the application.

To apply for special management, waste generators must submit a written application to the Director General. The application must:

- Follow the guidelines for special management as prescribed by the Director General.

- Include a non-refundable fee of RM300.

If the Director General is satisfied with the application, they may grant written approval, either with or without specific conditions. This flexibility allows businesses to tailor their waste management processes to their unique operational needs while ensuring compliance with environmental regulations.

Special management of scheduled waste can be particularly beneficial for industries with complex waste streams or those seeking to implement innovative on-site treatment solutions. By leveraging this provision, waste generators can enhance efficiency, reduce costs, and contribute to sustainable waste management practices.

Responsibilities of Transporters

In the scheduled waste management framework in Malaysia, transporters play a vital role in ensuring the safe and compliant transportation, treatment, and disposal of scheduled waste. The Environmental Quality (Scheduled Wastes) Regulations 2005 outline specific responsibilities for transporters to minimize environmental risks and ensure adherence to legal requirements. Below are the key responsibilities of transporters as per the regulations:

Licensing and Compliance

Transporters must obtain a Scheduled Waste Transporter License from the DOE under subsection 18(1A) of the Environmental Quality Act 1974. This license ensures that only qualified and authorized entities are involved in the transportation and handling of scheduled waste. Transporters must comply with all conditions specified in their license and adhere to the guidelines set by the DOE.

Proper Transportation of Scheduled Waste

Regulation 13 requires transporters to transport scheduled waste in a manner that prevents spills, leaks, or accidents. Key responsibilities include:

- Using approved vehicles and containers that are compatible with the type of scheduled waste being transported.

- Ensuring that scheduled waste is properly packaged and labelled according to the Third Schedule.

- Avoiding densely populated areas, water catchment zones, and environmentally sensitive areas when selecting transportation routes.

- Carrying the Seventh Schedule for each category of scheduled waste during transportation and complying with the instructions contained therein like:

- The waste’s properties (e.g., category, origin, physical properties, risks)

- Handling instructions (e.g., personal protection equipment, procedures, labeling, disposal methods)

- Precautions for spills or accidental discharges (including first aid and medical guidelines)

- Steps to be taken in case of spills or accidental discharges causing environmental damage (e.g., spills on land or water, fires, explosions).

Handover to Treatment or Disposal Facilities

Transporters are responsible for delivering scheduled waste to licensed treatment or disposal facilities as specified in the Consignment Note.

Spill or Accidental Discharge Response

In the event of a spill or accidental discharge during transportation, transporters must:

- Immediately inform the Director General (Regulation 14).

- Take all necessary steps to contain, cleanse, or abate the spill and recover any substances involved.

- Conduct studies to determine the environmental impact of the spill, as directed by the DOE.

Employee Training

Transporters must ensure that all employees involved in the handling, transportation, and storage of scheduled waste attend training programs (Regulation 13(5)). These programs should cover:

- Proper handling and transportation procedures.

- Emergency response measures for spills or accidents.

- The purpose and use of the Seventh Schedule and other relevant documentation.

Compliance with Audits and Inspections

Transporters must be prepared for audits and inspections by the DOE to verify compliance with scheduled waste regulations. Non-compliance can result in penalties, fines, or the revocation of their license.

Responsibilities of Facility Operators

Disposal or treatment facilities are critical players in the scheduled waste management process in Malaysia. These facilities are responsible for the safe and environmentally sound treatment, recovery, and disposal of scheduled waste. The Environmental Quality (Scheduled Wastes) Regulations 2005 outline specific responsibilities for facility operators to ensure compliance with legal requirements and minimize environmental risks. Below are the key responsibilities of facility operators as per the regulations:

Licensing and Compliance

The disposal or treatment facilities must obtain a Scheduled Waste Facility License from the DOE under subsection 18(1) of the Environmental Quality Act 1974. This license ensures that only authorized and qualified facilities are involved in the treatment and disposal of scheduled waste. Facilities must comply with all conditions specified in their license and adhere to the guidelines set by the DOE.

Acceptance of Scheduled Waste

Facility operators are required to accept scheduled waste only from licensed transporters and ensure that the waste is accompanied by a Consignment Note (as per the Sixth Schedule). Upon receiving the waste, facilities must:

- Verify the details provided in the Consignment Note, including the waste category, quantity, and origin.

- Complete the Receiver’s part of the Consignment Note via the eSWIS system to update the status and its respective received waste information.

Proper Treatment and Disposal

Facility operators are responsible for ensuring that only permitted waste is accepted and that appropriate treatment is undertaken to minimize hazards before final disposal.

- Treatment Methods:

- Incineration: High-temperature burning of waste to reduce its volume and neutralize hazardous components. This method is suitable for organic wastes, clinical wastes, and other combustible materials.

- Chemical Treatment: Using chemical processes to neutralize, stabilize, or detoxify hazardous waste. For example, acidic or alkaline wastes can be neutralized to render them less harmful.

- Physical Treatment: Processes such as filtration, sedimentation, or encapsulation to reduce the hazardous nature of waste. This method is often used for sludges or solid wastes.

- Landfill Disposal: Non-recyclable and non-hazardous scheduled waste that cannot be treated or recovered must be disposed of in secure landfills. These landfills are designed to prevent leaching and contamination of soil and groundwater.

- Recycling and Recovery: Facility operators are encouraged to recover valuable materials from scheduled waste whenever possible. Examples include:

- Metal Recovery: Extracting metals such as copper, lead, and cadmium from electronic waste or industrial sludges.

- Oil Re-refining: Reprocessing used lubricating oils to produce reusable base oils.

- Solvent Recovery: Distilling and purifying spent solvents for reuse in industrial processes.

- Residual Management: Any residuals from treatment or recovery processes must be further treated or disposed of at prescribed premises to ensure they are rendered innocuous.

Spill or Accidental Discharge Response

In the event of a spill or accidental discharge at the treatment facility, the facility operators must:

- Immediately inform the Director General of Environmental Quality (Regulation 14).

- Take all necessary steps to contain, cleanse, or abate the spill and recover any substances involved.

- Conduct studies to determine the environmental impact of the spill, as directed by the DOE.

Employee Training

Facility operators must ensure that all employees involved in the handling, treatment, and disposal of scheduled waste attend training programs. These programs should cover:

- Proper handling and treatment procedures.

- Emergency response measures for spills or accidents.

- Compliance with regulatory requirements.

Compliance with Audits and Inspections

Facility operators must be prepared for audits and inspections by the DOE to verify compliance with scheduled waste regulations. Non-compliance can result in penalties, fines, or the revocation of their license.

Best Practices for Packaging and Labelling Scheduled Wastes

Identification of Scheduled Waste

Proper identification of scheduled waste is the first and most critical step in ensuring safe and compliant waste management. Misclassification can lead to improper handling, storage, and disposal, posing significant risks to human health and the environment. Here’s a step-by-step guide to identifying scheduled waste:

Step 1: Obtain a Description of the Waste

Request a comprehensive description of the waste from the producer or generator. This should include the following key details:

- Source of the Waste: Specify the process or activity that generates the waste.

- Materials Involved: List the raw materials, intermediates, and by-products associated with the waste generation process.

- Safety Data Sheet (SDS): Request the SDS (if any) for all substances involved, highlighting their chemical composition and safety information.

- Hazardous Properties: Identify any known hazardous characteristics, such as flammability, corrosivity, reactivity, or toxicity, based on the information available.

Step 2: Check the First Schedule

Refer to the First Schedule of the Environmental Quality (Scheduled Wastes) Regulations 2005 to determine if the waste is listed as scheduled waste. If the waste is clearly listed, proceed with the appropriate classification and handling procedures.

Step 3: Determine Basic Properties

Analyze the physical and chemical properties of the waste, such as:

- Physical State: Is the waste a solid, liquid, or gas?

- Composition: What are the main components of the waste?

Step 4: Assess Hazardous Properties

If the waste is not listed in the First Schedule, assess whether it exhibits hazardous properties, such as:

- Corrosivity: Can the waste corrode metals or damage living tissue?

- Flammability: Is the waste easily ignitable?

- Toxicity: Does the waste contain substances that are harmful or poisonous, posing risks of injury, illness, or environmental harm?

- Reactivity: Can the waste react dangerously with water, air, or other chemicals?

- Explosiveness: Does the waste have the potential to explode under certain conditions?

- Infectiousness: Could the waste contain infectious substances that may pose a risk to human or animal health?

- Miscellaneous Dangerous Substances: Does the waste fall into a category of hazardous substances that do not fit neatly into the above properties but are still dangerous?

Step 5: Conduct Waste Analysis (if necessary)

If the waste’s classification is unclear, conduct a detailed analysis to identify its components and hazardous properties. Use laboratory testing or consult with certified waste management professionals to ensure accurate classification.

Step 6: Classify the Waste

Based on the description, properties, and analysis, classify the waste according to the First Schedule of the regulations. Assign the appropriate scheduled waste code for identification and labeling purposes.

Selecting the Right Containers

Once the waste is properly identified, the next step is to select the appropriate containers for storage. Key considerations include:

Types of Containers

| Type of Containers | Type of Scheduled Wastes | Requirements |

|---|---|---|

Bunghole Drum (Steel/Plastic) | No hole, no bulge, and free of dent and corrosion. | |

Open Top Drum with Cover & Clamp (Steel/Plastic) | No hole, no bulge, and free of dent and corrosion. | |

Intermediate Bulk Container (IBC) | Used for a broad range of waste stream such as oils, solvents and acids. | No hole or crack. |

Jerrican/ Carboy | Inorganic or organic liquid waste such as chemical wastes, solvents, etc. | No hole or crack. |

Containers for Clinical Waste | Clinical wastes or pathogenic wastes. | No hole or crack. |

Corrugated Box/ Carton Box | No tear or hole. | |

Flexible Intermediate Bulk Containers (FIBCs)/ Jumbo Bags |

Container Condition

- Ensure containers are free from damage, such as dents, holes, or corrosion.

- Regularly inspect containers for signs of wear and tear.

Compatibility

- Use containers made of materials that are chemically compatible with the waste. For example, avoid storing corrosive acids in metal containers.

- Rinse containers thoroughly before reuse if they previously held incompatible wastes.

Proper Labelling of Containers

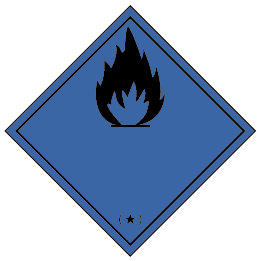

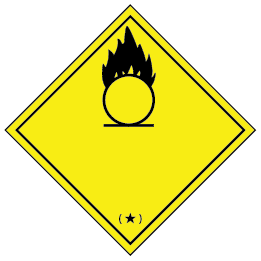

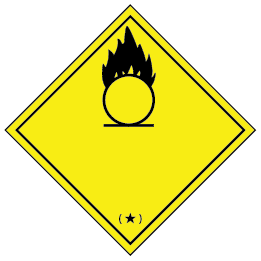

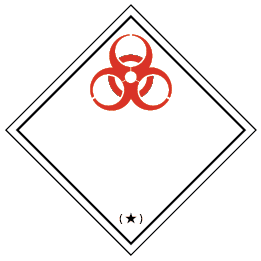

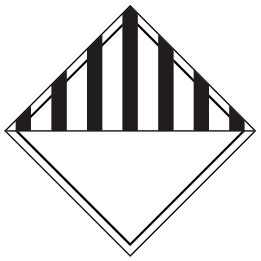

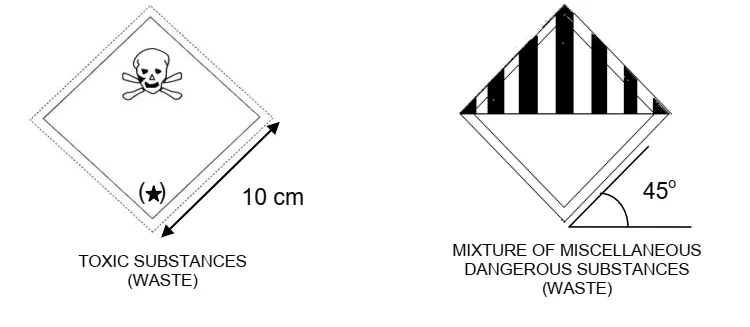

Accurate labelling is essential for safe handling and compliance with regulations. Under the Third Schedule of the Environmental Quality (Scheduled Wastes) Regulations 2005, it outlines the labelling requirements for scheduled wastes. The schedule includes 11 different labels, each corresponding to a specific type of hazardous waste.

| Label | Hazard Characteristics | Requirements |

|---|---|---|

| Label 1: Explosive Substances (Waste) | |

| Label 2: Inflammable Liquids (Waste) | |

| Label 3: Inflammable Solids (Waste) | |

| Label 4: Solid: Spontaneously Combustible (Waste) Substance liable to spontaneous combustion. | |

| Label 5: Solid: Dangerous When Wet (Waste) Substances which, if in contact with water, emit inflammable gases. | |

| Label 6: Oxidizing Substances (Waste) | |

| Label 7: Organic Peroxides (Waste) | |

| Label 8: Toxic Substances (Waste) Poisonous (toxic) substances | |

| Label 9: Infectious Substances (Waste) | |

| Label 10: Corrosive Substances (Waste) | |

| Label 11: Mixture of Miscellaneous Dangerous Substances (Waste) |

Required Information

- Date of Waste Generation: The date when the waste was first produced.

- Waste Generator Details: Name, address, and telephone number of the manufacturer.

- Scheduled Waste Code: A code from the First Schedule of the Environmental Quality (Scheduled Wastes) Regulations 2005.

You can download the Word templates for all 11 Scheduled Waste Labels and customize them as required, or you may download the labels via eSWIS system directly.

Hazard Symbols and Labels

Labels must include hazard symbols as specified in the Third Schedule and each label must be at least 10 cm x 10 cm (except where the size of the container or package warrants for a label of smaller size) and placed at a 45-degree angle for visibility. If waste poses multiple hazards, all hazards must be clearly identified, and the waste must be appropriately labeled to reflect each hazard.

Label Durability

Labels must withstand weather conditions and remain legible over time. Use stick-on labels, metal plates, or stenciled markings depending on the container type.

Designing and Managing Storage Areas

Site Selection Criteria

Choosing the right location for storing scheduled waste is critical to ensure safety and compliance. Here are the key considerations:

On-Site Storage

- Location: The storage area should be located away from manufacturing or processing areas, employee activity zones, and sources of heat or fire.

- Flood Risks: Avoid areas prone to flooding or located near slopes or hill edges.

- Accessibility: Ensure the storage area is easily accessible for waste collection and emergency response.

Off-Site Storage

- Zoning Compliance: Off-site storage facilities must comply with the Guidelines for the Siting and Zoning of Industrial and Residential Areas published by the DOE.

- Industrial Areas: Off-site facilities should be located within designated industrial zones.

- Flood Prevention: Avoid flood-prone areas to prevent contamination of surrounding environments.

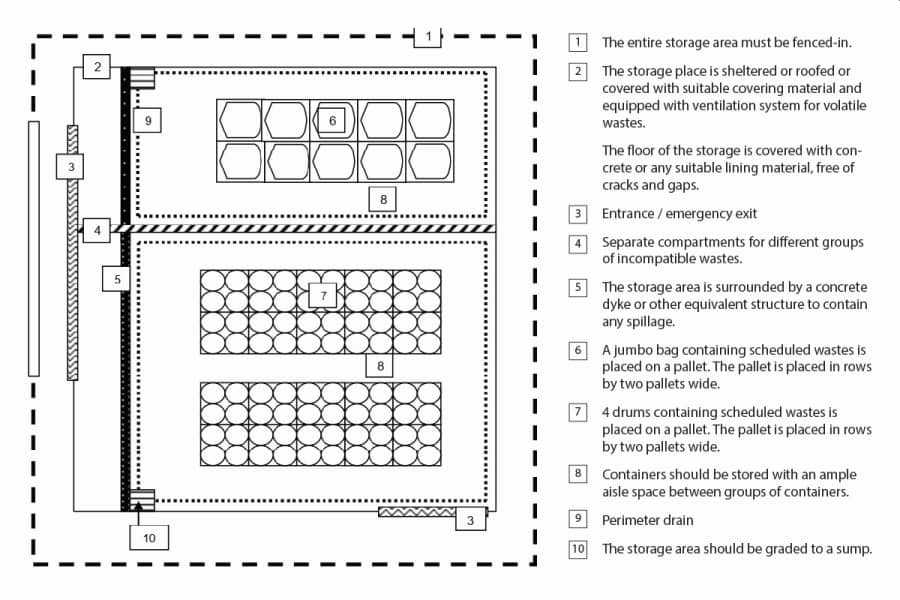

Storage Area Design

The design of the storage area must prioritize safety, containment, and compliance. Key design elements include:

- Fenced and Restricted: The entire storage area is fenced and marked with clear signage (e.g., “DANGER: SCHEDULED WASTES STORAGE”).

- Concrete Flooring: The floor is covered with concrete or a suitable lining material, free of cracks and gaps.

- Organized Layout: Containers are stored in rows, with ample aisle space for inspection and emergency access.

Design Capacity

The storage area must be designed to provide sufficient space for all scheduled wastes generated or managed on the premises. The design capacity should account for the following:

- Storage Capacity: including an additional 25% storage capacity beyond the actual maximum amount of waste generated.

- Storage Duration: limiting storage duration to no more than 180 days or as specified by the DOE.

Secondary Containment

- Concrete Dikes: Surround the storage area with concrete dikes or equivalent structures to contain spills. The containment capacity should be 110% of the largest container stored in the area.

- Sump and Drainage: Grade the dike area to a sump for collecting spilled liquids. Ensure proper drainage to prevent rainwater or surface water from entering the storage area.

Shelter and Ventilation

- Roofing: The storage area should be sheltered or roofed to protect containers from weather conditions.

- Ventilation: Install ventilation systems for volatile wastes to prevent the buildup of hazardous fumes.

Fire Safety

- Equip the storage area with firefighting equipment, such as fire extinguishers and sprinkler systems.

- Ensure compliance with the requirements of the Fire and Rescue Department of Malaysia.

Emergency Access

- Provide clear emergency escape routes and ensure adequate aisle space for easy movement of personnel and equipment.

Segregation of Incompatible Wastes

Mixing incompatible wastes can lead to dangerous reactions, such as fires, explosions, or the release of toxic gases. Follow these guidelines:

- Separate Compartments: Designate separate compartments or areas for storing incompatible wastes to prevent hazardous reactions.

- Potential Incompatibility: Refer to the Fourth Schedule of the regulations or the compatibility chart for chemical mixture to identify potential hazards when mixing wastes.

| Potential Consequences | Group A | Group B |

|---|---|---|

| Group 1: Heat generation, violent reaction | Alkaline caustic liquids, Alkaline cleaner, Alkaline corrosive liquid, Caustic wastewater, Lime sludge and other corrosive alkalies. | Acid sludge, Chemical cleaners, Electrolyte, acid, Etching acid, liquid or solvent, Pickling liquor and other corrosive acid, Spent acid, Spent mixed acid. |

| Group 2: Release of toxic substances in case of fire or explosion. | Asbestos, Beryllium, Unrinsed pesticide containers, Pesticides. | Solvents, Explosives, Petroleum, Oil and other flammable wastes. |

| Group 3: Fire or explosion; generation of flammable hydrogen gas. | Aluminum, Beryllium, Calcium, Lithium, Magnesium, Potassium, Sodium, Zinc powder and other reactive metals and metal hydrides. | Any waste in Group 1-A or 1-B. |

| Group 4: Fire, explosion or heat generation; generation of flammable toxic gases. | Alcohols. | Any concentrated waste in Group 1-A or 1-B, Calcium, Lithium, Metal hydrides, Potassium, Sodium, Water reactive wastes. |

| Group 5: Fire, explosion or violent reaction. | Alcohols, Aldehydes, Halogenated hydrocarbons, Nitrated hydrocarbons and other reactive organic compounds and solvents, Unsaturated hydrocarbons. | Concentrated Group 1-A or 1-B wastes, Group 3-A wastes. |

| Group 6: Generation of toxic hydrogen cyanide or hydrogen sulphide gas. | Spent cyanide and sulphide solution. | Group 1-B Wastes. |

| Group 7: Fire, explosion or violent reaction. | Chlorates and other strong oxidizers, Chlorites, Chromic acid, Hypochlorites, Nitrates, Nitric acid, Perchlorates, Permanganates, Peroxides. | Organic acids, Group 2-B wastes, Group 3-B wastes, Group 5-A wastes and other flammable and combustible wastes. |

Loading and Unloading Areas

- Spill Containment: Design loading and unloading areas to contain any spills during waste transfer.

- Pallet Storage: Place containers on pallets to prevent direct contact with the floor and facilitate easy movement.

Regular Inspections and Record-Keeping

Regular inspections are a cornerstone of effective scheduled waste management. They help ensure compliance with regulations, identify potential hazards, and prevent accidents. Here’s why inspections are critical:

- Prevent Leaks and Spills: Early detection of container damage or leaks can prevent environmental contamination.

- Ensure Compliance: Inspections help manufacturers stay compliant with the Environmental Quality (Scheduled Wastes) Regulations 2005.

- Safety Assurance: Regular checks ensure that storage areas and containers are safe for workers and the surrounding environment.

Inspection Checklist

A standardized inspection checklist should be used to monitor the storage area and containers. Key items to include are:

| Key Item | Inspections |

|---|---|

| Container Condition | |

| Labelling | |

| Storage Duration | |

| Secondary Containment | |

| Aisle Space and Accessibility | |

| Fire Safety |

Frequency of Inspections

- Weekly Inspections: Conduct thorough inspections of the storage area and containers on a weekly basis.

- Immediate Action: Address any issues identified during inspections promptly to prevent accidents or non-compliance.

Record-Keeping Requirements

Accurate record-keeping is essential for compliance and accountability. Under Regulation 11, the waste generators shall prepare an accurate and up-to-date inventory of scheduled wastes. All these records and relevant documentations must be retained for at least three years from the date of waste generation. Here’s what manufacturers need to document:

Inventory Records

- Maintain a detailed inventory of all scheduled wastes as per the Fifth Schedule of the regulations, including:

- Type of waste (e.g., corrosive, flammable, toxic).

- Quantity of waste stored.

- Date of waste generation and storage.

- Update the inventory regularly and make it accessible for inspections.

Inspection Logs

- Keep a log of all inspections, including:

- Date and time of inspection.

- Findings and actions taken.

- Name of the inspector.

- Use a standardized inspection checklist for consistency.

Waste Transfer Records

- Document all transfers of scheduled waste to prescribed premises for treatment or disposal.

- Include details such as the date of transfer, quantity of waste, and destination facility.

Emergency Preparedness and Employee Training

Scheduled waste storage areas are potential hotspots for accidents, such as spills, leaks, fires, or explosions. Having a robust emergency preparedness plan is essential to minimize risks and ensure the safety of workers and the environment. Here’s why it matters:

- Quick Response: A well-prepared team can respond swiftly to emergencies, reducing the impact of accidents.

- Compliance: Emergency preparedness is a regulatory requirement under the Environmental Quality (Scheduled Wastes) Regulations 2005.

- Reputation: Effective emergency management demonstrates a company’s commitment to safety and environmental responsibility.

Emergency Preparedness Plan

| Key Item | Description |

|---|---|

| Emergency Procedures |

|

| Emergency Equipment | |

| Emergency Contacts |

|

| Evacuation Routes |

Employee Training

Proper training is critical to ensure that employees can handle scheduled wastes safely and respond effectively to emergencies. Key training areas include:

Waste Handling and Storage

- Train employees on proper techniques for packaging, labeling, and storing scheduled wastes.

- Emphasize the importance of using personal protective equipment (PPE) and train employees on the proper use, maintenance, and disposal of PPE. Examples of the PPE:

- Gloves: Chemical-resistant gloves for handling corrosive or toxic wastes.

- Goggles and Face Shields: Eye protection for working with hazardous liquids or powders.

- Respirators: For protection against toxic fumes or dust.

- Protective Clothing: Coveralls or aprons to prevent skin contact with hazardous materials.

Emergency Response

- Conduct regular training sessions on emergency procedures, including spill containment, firefighting, and evacuation.

- Simulate emergency scenarios to test employees’ readiness and identify areas for improvement.

Regulatory Compliance

- Educate employees on the legal requirements for scheduled waste management, including the Environmental Quality (Scheduled Wastes) Regulations 2005.

- Provide updates on any changes to regulations or company policies.

Certification Programs

- Encourage employees to participate in certification programs for scheduled waste management, such as those offered by the Environmental Institute of Malaysia (EiMAS).

- Certified waste managers can oversee waste management activities and ensure compliance with regulations.

Conclusion

Proper management of scheduled waste is not just a legal obligation for manufacturers in Malaysia—it’s a critical responsibility that protects human health, the environment, and the long-term sustainability of businesses. By adopting best practices in waste management, manufacturers can:

- Protect the Environment: Prevent pollution and conserve natural resources.

- Enhance Safety: Reduce the risk of accidents and health hazards for workers.

- Improve Efficiency: Lower operational costs through waste minimization and recycling.

- Build Reputation: Demonstrate corporate responsibility and gain the trust of customers, regulators, and the community.

Manufacturers in Malaysia have a unique opportunity to lead by example in scheduled waste management. Here’s what you can do:

- Assess Your Current Practices: Evaluate your waste management processes to identify areas for improvement.

- Invest in Training: Provide employees with the knowledge and skills they need to handle scheduled waste safely and effectively.

- Engage Experts: Work with certified scheduled waste expert like us to ensure compliance and optimize your waste management strategies.

- Adopt Sustainable Practices: Implement waste minimization and circular economy initiatives to reduce your environmental impact.

- Stay Informed: Keep up-to-date with regulatory changes and industry best practices to continuously improve your waste management efforts.

For expert guidance on scheduled waste management, Metahub is here to help. Metahub is a licensed waste management company in Malaysia specializing in scheduled waste disposal. With our expertise in handling wastes like SW104, SW110, SW204, SW206, and SW401, we ensure your business stays compliant while minimizing environmental impact. To explore the full list of approved scheduled wastes we manage, visit Our Services page for more details.

Our Key Advantages

- 20 Years of Experience: Established since 2005, we are one of the largest recyclers & full-time waste management companies based in Johor, Malaysia.

- Large Approved Quota: Our substantial approved quota allows us to handle large volumes of waste disposal, accommodating even the most demanding requirements.

- Sustainable Practices: Focus on developing ecologically friendly alternatives to repurpose resources derives from a wide range of industrial wastes.

- Zero Discharge Technology: Our state-of-the-art wastewater treatment plant utilizes zero discharge technology, aligning with the Selangor Zero Discharge Policy and supporting your company’s sustainability goals.

Get in touch with Metahub today to understand how our scheduled waste management solutions can help your business meet its scheduled waste disposal obligations. Contact us for a consultation and let’s ensure your waste is managed responsibly and legally.